A guide of Landlord Electrical Safety Certificate research on many electrical problems around the house are caused by different versions of the same important problem. Cable connections that have been improperly made or loosened over time. You may have inherited the problem from the previous owner or an electrician who did the wrong job. Alternatively, it can be the result of the work you have done yourself. Many wiring problems are no one’s fault, but the result of time. The wire is under a constant cycle of heating and cooling, expanding and cooling. Every time you use a switch or connect a device, a natural consequence of all this use is that the wire connections can become loose over time.

Electrical systems have many safeguards against the dangers of poor wiring, including grounding systems, circuit breakers, GFCI and AFCI protection. Still, wireless connections in the system pose a risk of sparks and arcing. Most of these issues are very easy for homeowners to find and fix, while other issues are best handled by a Landlord Electrical Safety Certificate. Understanding where these problems occur most often can help you decide how to solve them.

- Tools and materials

- Flashlight

- wire mesh

- Driver

- Utility knife

- Wire connector (wire nut)

- Eye protection

- Wires of different gauges

Here are the six most common places where cable connection problems occur.

The wire connection between the switch and the outlet is loose

The most common problem is when the wall switch and the fixed terminals on the outlet are easily connected. These are the most used tools in the electrical system, so if you suspect a wiring problem, you should check these tools first. If the switch, outlet, or lighter wire connection is loose, the symptom is often manifested by humming, crackling, or flashing light.

To solve this problem, you must first turn off the suspicious wall switch, light or outlet. With the power off, you can remove the cover plate and use a flashlight to carefully examine the internal thread terminals where the wires are connected. If you find anything loose, carefully solder the terminals attached to the wire. Maybe this will solve the problem.

In some cases, the wiring can be done through a push-fit fitting on the back of the switch or outlet. This method of communication is notoriously prone to failure. As a result, Landlord Electrical Safety Certificate never use push-in fittings and instead make all wiring connections through crimp terminal connections on the side of the switch or outlet. .. If you find that your appliances are made with push fittings, it is recommended that you remove them and reconnect the cables to the terminals on your appliance.

Finally, if the box has pass-through wire connectors made with wire nuts or other types of fasteners, check these to make sure the wires are securely attached. Loose connectors are also a common cause of problems.

Wire connection made of electrical tape

A classic wiring error is when the wires are connected with electrical tape instead of wire nuts or other approved connectors. To solve this problem, first turn off the circuit. Be sure to check the correct amount of exposed wire (for most connectors this means about 3/4 inch) and connect the wires with wire nuts or other approved fasteners. (There are push links that some professionals like to use).

If the end of the wire is damaged, you can cut the end of the wire and strip off about 3/4 inch of insulation to make the proper wire nut connection.

Two or more wires under one terminal

Another common wiring problem is when two or more wires are attached to a switch under a single-threaded terminal. This is a clear amateur job and a clear fire hazard. It is permissible to place one wire under each of the two window terminals on the outside or side of the switch, but twisting the two wires under one coil is a code violation. If you find two bare copper wires from inside or by switching, this is usually the case, but you will find a hot or neutral wire connected to a single terminal.

To solve this problem, once again, this repair involves turning off the power first. Then disconnect the two problem wires from the quick terminals. Cut a 6-inch pigtail wire of the same color as the two wires (use the green pigtail to join the two bare copper ground wires). Remove the 3/4 inch insulator from both ends of the pigtail and use a wire connector (wire nut) to connect one end to the two cut wires. Then attach the free end of the pigtail wire to the plug terminal that holds the two wires at once. Basically, you have created a bridge or path that connects both wires to the desired wire terminal outlet or switch.

Note: Make sure the pigtail wire is the same wire gauge as the circuit wire. 15 amp circuits typically use 14 gauge wire.

Exposed wire

Especially in London, United Kingdom the Landlord Electrical Safety Certificate work. If there are too many (or too few) exposed copper wires. The wires often show broken terminal connections or wire nut connections. Connecting the broken terminal requires enough bare copper wire to completely wrap the broken terminal, but not enough bare copper wire to extend beyond the spigot. It’s a delicate balance. If too little copper wire is exposed, the cone may rest on the insulator instead of the wire when it is soldered. Too many exposed wires can cause a short circuit if connected to a metal box or other wire. The wire should be wound clockwise around the crimped terminal. If they are flipped, they tend to loosen.

The wire nut connection must hide. All the bare copper wire under a plastic cap so that the exposed wire is not visible on the underside of the wire. To solve this problem, turn off the device. Disconnect the cables and cut the excess wires or remove additional insulation to expose the correct amount of wire. Then reconnect the wire to the thread terminal or wire nut. Pull gently to make sure the wire is securely connected.

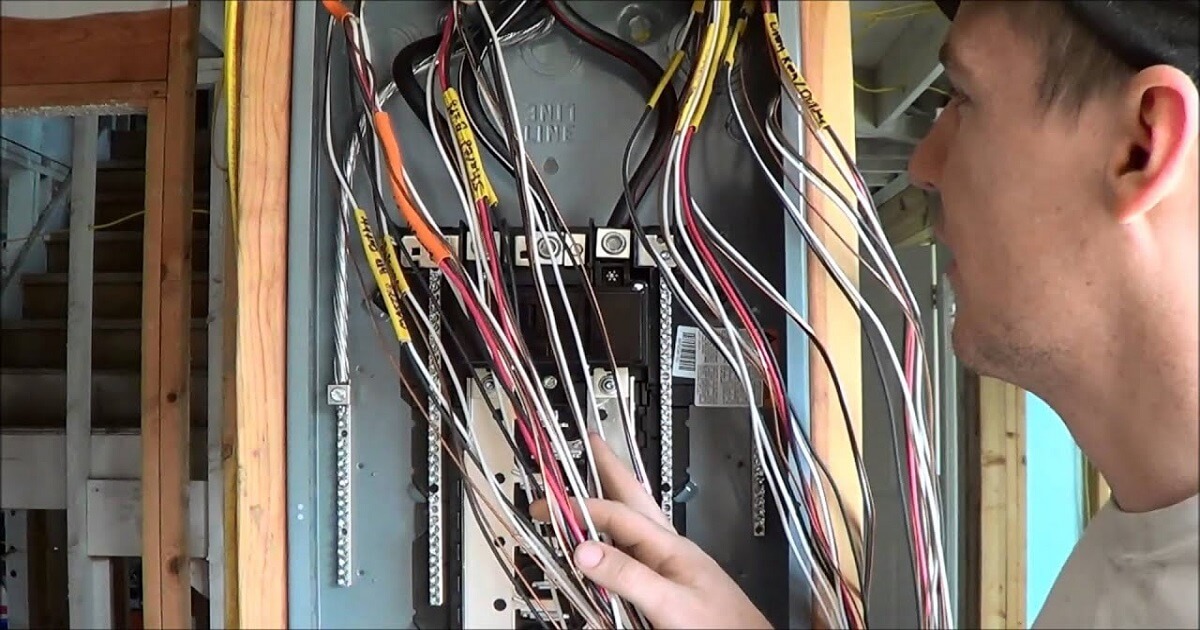

The circuit breaker terminal connection is loose

A less common problem is when the circuit breaker’s hot wire on the main. Service panel is not securely connected to the breaker. When this happens, the components in the entire circuit may flicker or cause service problems. When connecting to a circuit breaker. Remove the appropriate amount of wire insulation from the wires and ensure that only bare wires are located under the terminal slots before crimping. The insulation under the connection slot is a code violation.

To solve this problem, the main service panel must be repaired by Landlord Electrical Safety Certificate. Amateurs should attempt these repairs only if they have sufficient experience and knowledge of electrical systems.

Professional electricians can fix this problem by turning off the breaker and removing the clip from. The hot bus bar on the main service panel. He or she checks the hot wire connected to the breaker to make sure. It’s tight, that there’s no insulation under the terminals, and that no more bare copper wire is exposed. When the repair is complete, the electrician places. The breaker on the hot bus bar and turns the breaker back on.

Poor neutral connection on the circuit panel

Another less common problem. And one that professionals often encounter, is when the white circuit line is not properly installed in the neutral bus of the main service panel. The symptoms here are similar to a hot wire failure. To solve this problem, the Landlord Electrical Safety Certificate will make sure that the neutral wire is sufficiently stripped and properly connected to the neutral bus read more blogs.